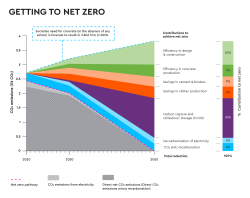

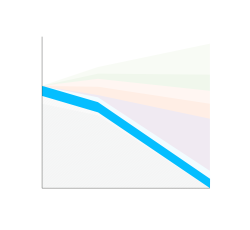

Total global CO2 emissions from the sector today are in excess of 2.5Gt. They are primarily direct CO2 emissions which in turn are primarily from the heated limestone itself (approx. 60%) and combustion of the fuels used in the cement kiln and other plant processes (approx. 40%). Electricity used by the sector contributes further CO2 emissions as shown. There are multiple levers that will be implemented to reduce CO2 emissions at different stages of the whole life of cement and concrete. Our roadmap process has evaluated the role that each of these levers will play to reach net zero. The global average is presented in the graph below. Across the world each lever will be implemented in accordance with local factors.

01 / Emissions from pure waste biomass and from the biogenic carbon content of mixed fuels is considered as climate neutral in accordance with the Greenhouse Gas Protocol

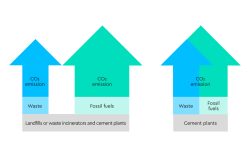

Utilisation of waste fuels in cement plants results – according to the Greenhouse Gas Protocol – in CO2 and even GHG emission reductions at landfills and incineration plants.

01 / Binder means all material in concrete such as cement, fly ash, ggbs, limestone fines etc. that is permitted as cementing material in the local jurisdiction

02 / Clinker is produced in a cement kiln and is ground to manufacture ordinary Portland cement. Clinker can be ground with other materials to produce cements with lower CO2 emissions

01 / “CO2 uptake in cement containing products” www.ivl.se/co2-uptake-concrete