Carbon capture, utilisation and storage (CCUS) describes processes that capture CO2 emissions from industrial sources, and either reuses them in other industrial activity or stores them for centuries or millennia so that they will not enter the atmosphere.

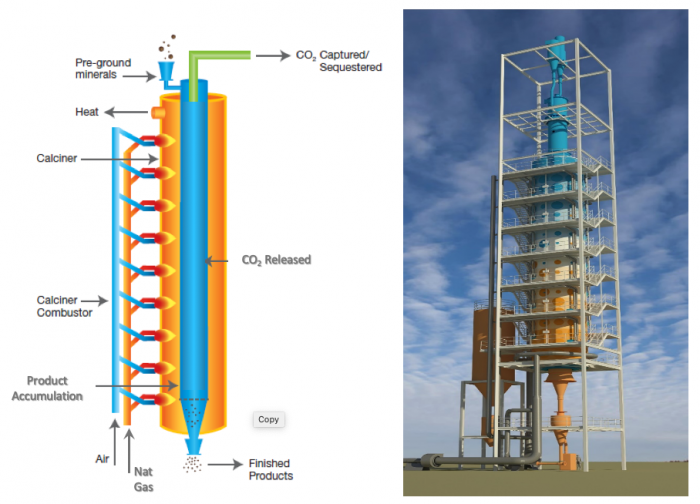

CCUS is a crucial solution for the cement sector where a large share of emissions are not energy related but are due to the specific chemistry of cement making. CCUS is a cornerstone (36%) of our net zero carbon roadmap for cement and concrete. The technology has been shown to work and is close to maturity but an industry-wide roll out of CCUS will require close cooperation between the industry, policymakers and the investment. CO2 capture is still expensive today, but technology is improving and the significant number of demonstration facilities, currently being deployed in cement production, demonstrates the potential for significant cost reduction in the years ahead.

While the technology is advancing, the economics remain challenging. The development of a ‘carbon economy’ is therefore an essential step in the move from a limited number of case studies to widespread deployment. Part of this journey is the re-evaluation of CO2 as a usable commodity rather than a waste product.

Learn more about the CCUS projects in cement plants around the world

Read more

CCUS is a critical lever in our 2050 Net Zero. Learn more in our Policy Paper

Read more

The construction industry can play its part in developing an economy for CO2 – and there are signs that this is happening. The process of carbonation (long considered a nuisance by concrete engineers) is opening up a range of opportunities to permanently sequester CO2 in building materials.

Outside of the construction industry, there are few technologies available at commercial scale that could consume CO in large quantities. Beyond its established use in enhanced oil recovery, the most traditional uses for CO2 are urea production, Sabatier synthesis, Fischer-Tropsch synthesis, hydrogenation to methanol, dry reforming, hydrogenation to formic acid, and electrochemical reduction.

Biological methods of CO2 capture and utilisation are also being developed, The treatment of flue gas by microalgae – which effectively ‘eat’ the CO2 – has the advantage of being relatively low cost, while producing a material (the algae) that can be processed for onward use in bioplastic production, biofuels, or fertilizer production. In one notable example from the cement industry, the algae are processed into food for the local fishery industry.