UltraTech signed a collaboration agreement with the Institute for Carbon Management (ICM) at the University of California, Los Angeles (UCLA) to pilot a groundbreaking new technology The Zero Carbon Lime (ZeroCAL) developed by ICM that can significantly reduce carbon dioxide emissions from cement production. ICM, in partnership with UltraTech, will build a first-of-a-kind demonstration plant for the technology at one of UltraTech’s integrated cement manufacturing units.

The Zero Carbon Lime (ZeroCAL) process, developed by ICM researchers, can eliminate nearly 98% of carbon dioxide emissions associated with limestone decomposition in cement manufacturing. UltraTech will be the first company globally to implement the ZeroCAL process at scale through a demonstration plant that will produce several metric tons of zero-carbon lime per day.

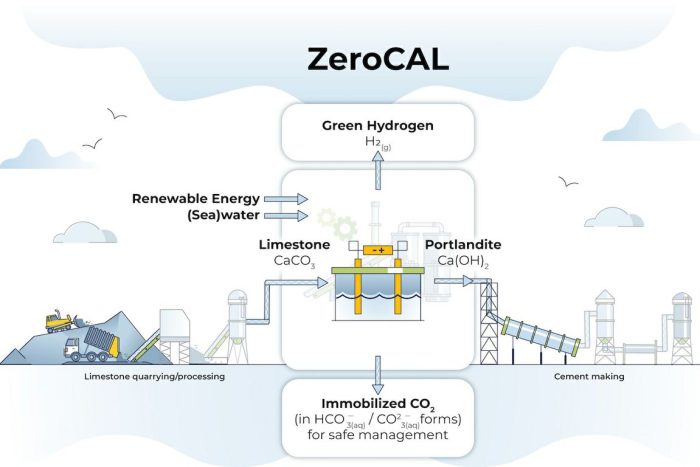

In the existing cement production process, the calcination of limestone in the preheater causes carbon dioxide to be released in the atmosphere. The ZeroCAL process produces calcium hydroxide by electrochemically decomposing limestone in water without resulting in carbon dioxide emission. The major advantage of the ZeroCAL process is its compatibility with the existing cement manufacturing process. Calcium hydroxide, the key product of the ZeroCAL process, is simply dewatered and is fed as a drop-in replacement (for limestone) into the cement kiln.

To accelerate its decarbonisation efforts, UltraTech is collaborating with technology startups to explore the use of emerging decarbonisation technologies including kiln electrification and carbon capture & storage.