This Q&A document aims to address key questions about co-processing, including how it works, the types of waste it utilises, its benefits, and monitoring systems. With thanks to Cement Europe for the foundational work – see its document here.

1. What is Co-processing?

Co-processing of waste in cement kilns is an established, environmentally sound, and highly regulated waste management technology. It is a valuable option for a wide range of societal waste. In contrast to energy recovery, for example in waste to energy incinerators, co-processing does not only recover the energy content of the waste but also recycles its mineral content into high value cement and concrete products. Co-processing results in the reduction of fossil fuels and primary materials consumption as well as reduction in waste disposal.

2. Can the cement industry use all types of wastes? Which waste materials are most suitable for co-processing?

Waste used as an alternative fuel

The cement manufacturing process offers the necessary conditions to enable the use of many different types of waste materials that can replace a portion of conventional fossil fuels. Waste materials can be solid, liquid or a paste mixture and are defined by their origin, e.g. industrial, agricultural and municipal sources and by their specific features, e.g. hazardous and non-hazardous. The market availability largely defines the different types of fuels used in different countries.

Preparation of different types of combustible waste or waste with separate calorific fractions for use as fuel or raw material can be performed at special waste management facilities or at the cement plant.

The delivered waste derived fuels need to be stored at the cement plant and then organised for feeding to the cement kiln. As these calorific waste materials can replace primary fuel in cement kilns, a consistent waste derived fuel quality is essential (e.g. adequate calorific value, low metal, low halogen (e.g. chlorine) and ash content).

Typical waste used as alternative fuels in the clinker burning process e.g. are refuse derived fuels (RDF), plastics, used tires, animal meal, sewage sludge and construction demolition waste in North America.

Waste used as raw materials

The chemical suitability of waste used as raw materials is important as they provide the constituents required for the production of cement clinker. Desirable chemical elements are calcium, silicon, aluminium and iron as well as sulphur, alkalis and others.

Typical waste used as alternative raw materials in the clinker burning process e.g. is fly ash, used foundry sand and residues from the iron and steel manufacturing industry.

There are several requirements to consider in the selection and use of a waste as alternative fuel or raw material. The use of all alternative fuels and raw materials undergo an official licensing procedure including permit applications, detailed waste characterisation and laboratory testing, and an environmental or technical impact assessments. Special provisions (e. g. feeding point to the kiln, energy content, limiting values for trace element contents, sampling procedures etc.) are detailed in the permit.

- According to the GCCA Sustainability “Guidelines for co-processing fuels and raw materials in cement manufacturing” the following materials are not accepted by cement manufacturing as fuel or raw materials:

- Radioactive waste from the nuclear industry

- Electrical and electronic waste (e-waste)

- Whole batteries

- Corrosive waste, including minerals acids

- Explosives and ammunition

- Waste containing asbestos

- Biological medical waste

- Chemical or biological weapons destined for destruction

- Waste of unknown or unpredictable composition, including unprocessed municipal waste

- Waste raw materials with little or no mineral value for the clinker (i.e. heavy metal processing residues)

- There must be regular monitoring of inputs, e.g. sampling and analysis of the waste materials

- The fuels must have low volatile heavy metal concentration, i.e. mercury, thallium, and cadmium

Individual facilities may also exclude other materials depending on the local raw material and fuel chemistry, the infrastructure and the cement production process, the availability of equipment for controlling, handling and feeding the waste materials, and site-specific health, safety and environmental issues.

Contrary to other waste treatment solutions, co-processing is a zero-waste solution – as all the ‘ash’ produced by the combustion of waste fuels becomes an input material of the cement product.

3. Is co-processing in cement kilns compatible with recycling?

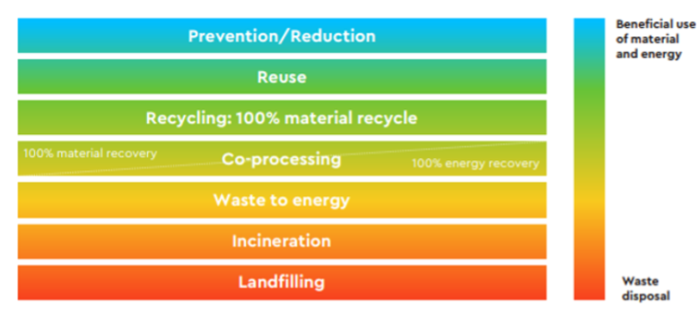

The waste hierarchy below is widely recognised and is applied in many countries (e.g. Norway, USA, UK, the EU). However, the use of waste in cement kilns is a combination of energy recovery and material recycling. Where waste materials cannot be managed technically or economically by prevention and reduction, reuse and recycling, the cement manufacturing process provides a more environmentally sustainable solution compared to landfill or incineration, thanks to the full energy and material recovery in the process.

Therefore, GCCA believes that co-processing should be recognised higher up in the waste hierarchy as per the following scheme:

4. What is the difference between waste incineration and co-incineration and between co-incineration and co-processing in a cement plant?

The main difference lies in the fact that the main purpose of cement plants is to produce cement whilst incinerators are dedicated facilities for the disposal of waste.

Co-processing is a type of co-incineration, unique to cement manufacturing, where waste is simultaneously used as both a source of energy and a source of mineral content in a single process. Additionally, it is a zero-waste solution.

In order to ensure a complete fuel burnout, the residence time of combustion gases has to be at least two seconds with a minimum temperature of 850°C. The typical residence time of combustion gases in the cement kiln main firing zone is more than five seconds at a temperature up to 2,000°C. In the second firing zone (calciner) residence time is also higher than two seconds with temperatures round about 1,000°C. Residence time for solid materials in cement kilns varies from 20 minutes to an hour depending on the cement process. The cement process also has integrated emission scrubbing systems through the raw mill which reduces emissions when compared to incinerators.

The clinker burning process – in contrast to other combustion processes (e.g. incineration plants) – consequently offers the best conditions for complete valorisation of alternative fuels.

5. Why the cement operators need strict quality control of the alternative fuels and raw materials?

The core business of the cement plant is not to co-process waste but to produce cement. The waste needs to have specifications that are suitable to produce the clinker which is used to manufacture cement products. Thus, strict quality control is required:

- To ensure the good functioning of the cement kiln system

- To ensure the quality of the clinker and cement

- To ensure the health and safety of the employees

- To minimise the impact on the environment

6. What is the gate-fee for the use of alternative fuels and raw materials during co-processing?

A cement plant will need to invest in various facilities which are necessary to feed the alternative fuels and raw materials into the cement kiln. The gate-fee can contribute to the necessary payback period to make this capital investment viable.

The gate-fee for the use of alternative fuels during co-processing is variable and depends on different factors such as the nature of alternative fuels, their quality, calorific value and their availability. Moreover, it should be highlighted that one of the main characteristics of the waste market is the high price volatility. It has been observed that the gate-fee for a certain alternative fuel changes from positive to negative during a specific time period or vice-versa.

Another factor that affects the gate-fee of the alternative fuels are the specific country’s and regional characteristics of the waste market, the availability of high-quality waste and the co-processing rate in many countries directly depends on the development of the waste management system in the country.

7. If the cement kilns were using only fossil fuels would the air emissions be lower?

The general answer is NO. Indeed, air emissions are mainly influenced by the natural raw material input, that is round about 85% of the whole material input compared to 15% input by the fuels.

More specifically:

- Dust: There is no difference between dust emissions when using alternative fuels or fossil fuels.

- Hydrogen chloride – HCI: Emissions vary irrespective of the fuel used.

- Hydrogen fluoride – HF: There is no difference in HF emissions when using alternative fuels.

- Nitrogen oxides – NOx: Alternative fuels do not lead to higher NOx emissions – in some cases, NOx emissions can even be lower when using alternative fuels.

- Mercury: Mercury emissions are mainly raw-material related. Furthermore, the input of mercury into the kiln system via the fuels is strictly controlled. As mercury is a high volatile element with the potential to build up mercury-circles in the kiln system, emission levels are highly influenced by operational and kiln-specific parameters and not by the type of fuel used.

- Heavy metals: Emissions vary irrespective of the fuel used. However, nearly 100% of them remain in the cement clinker matrix. In any event, alternative fuels undergo a rigorous acceptance and inspection procedure before being used which additionally controls the emissions to air. The input of trace elements into the kiln system of most alternative fuels is regulated in the permit and has therefore to be strictly controlled in practice.

- Polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans (PCDD/PCDF): No difference has been found in dioxin emissions when the diverse array of alternative fuels is used.

- Sulphur oxides – SO2: Alternative fuels have no influence on total SO2 emissions as these are mainly raw-material related.

- Total organic carbon – TOC: There is no correlation between the use of alternative fuels and TOC emissions levels as these are mainly raw-material related.

- Carbon monoxide (CO): Emissions are mainly raw-material related and cannot be influenced by the type of fuel used.

- Dioxins / Furans (D/F): Dioxins and Furans emissions are destroyed within cement kilns thanks to:

- long retention time of the gases in the kiln system

- high temperatures in the waste burning zone

- the excess of air in the kiln burning conditions

- low chlorine levels, which is an essential component to produce dioxins and furans. Chlorine is restricted in the specifications of alternative fuels and is also an undesirable element for cement kiln operation because it can create process difficulties.

- the lower temperatures of the exhaust gases due their utilisation for drying raw materials and cooling, prevents the formation of complex organic molecules like dioxins.

8. How do you ensure that emission monitoring systems are sufficient and transparent to the public?

Co-processing is a highly regulated process and operated in line with Best Available Technology/Best Environmental Practices. It is a recognised environmentally sound waste-treatment option. Long retention times, high temperatures and strict control of chlorine levels mean cements kilns have lower emissions to air than waste incineration plants. Waste materials undergo a rigorous acceptance and inspection procedure before being used in cement kilns. Application of Best Available Techniques (BAT) and Best Environmental Practices (BEP) ensure a high level of protection of human health and the environment. For example, the European Union regulates air emissions from industry, including cement manufacture.

Installations operate in accordance with a corresponding permit. Air emissions are measured according to specified provisions to ensure compliance with the limit values, and these are published on a regular basis. GCCA has Guidelines for the monitoring and reporting of emissions. The UNEP Basel Convention Technical Guidelines for waste co-processing provide instructions for the use of waste as alternative fuels in cement kilns. These address concerns of potential toxic emissions such as furans and dioxins when the conditions in the kilns are not properly controlled. Guidance must be followed, and close monitoring and quality control are essential to avoid negative impacts. The local regulations must provide strict control points for the cement kiln operation.

9. How can co-processing prevent global CO2 emissions?

Co-processing reduces the amount of waste that is incinerated, burnt or sent to landfill. As waste is shifted from incinerators to co-processing in cement kilns, the amount of CO2 emissions from waste incinerators and open waste burning are reduced.

Biogenic waste if sent to landfill or disposed of in an uncontrolled manner can lead to emissions of methane, a gas with global warming potential 28 times higher that of CO2. But these methane emissions can be avoided if this waste is redirected to cement kilns

10. Aren’t other solutions like CCS, green cement preferred, more effective and efforts should be put into these to develop?

CCS, green cement, and other emerging technologies are important, but they serve different roles, operate at different levels of maturity, and face different economic and technical barriers. Co-processing should not be deprioritised, as it is one of the fastest, cheapest, and most deployable decarbonisation tools available today. But it cannot fully decarbonise the sector alone. Development of other low carbon technologies must continue in parallel because they are essential for deep, long-term reduction of cement emissions.

11. How does co-processing shape innovation higher up the waste hierarchy? How does this differ in EMDE contexts, particularly where formal waste-collection systems are absent?

Co-processing can play a constructive role in driving innovation higher up the waste hierarchy as it is positioned as a solution to non-recyclable and non-reusable waste rather than a substitute for recycling. With the right regulatory frameworks, it can help create demand for better waste segregation and material recovery facilities, while still providing a solution for fractions that cannot yet be recycled.

In EMDE contexts, the dynamic is often different because formal collection and sorting systems may be limited, and waste management is frequently reliant on informal sectors. In such settings, co-processing can support the development of basic collection infrastructure and reduce open dumping or burning.

12. Is co-processing expected to be a short-term transitional measure, or a technology that will still play a significant role in the long-term?

We see co-processing as a long-term solution and an important lever on the cement decarbonisation pathway. It can permanently reduce the use of fossil fuels by substituting them with waste-derived and biomass-based fuels, with some cement plants already meeting over 90% of their energy needs through co-processing. Globally, the use of alternative fuels in cement production is forecast to increase from 6% in 2020 to 22% by 2030 and to 43% by 2050.

However, non-recyclable waste today may become recyclable tomorrow as technologies advance. We therefore respect the waste management hierarchy, where recycling solutions should take priority whenever possible.